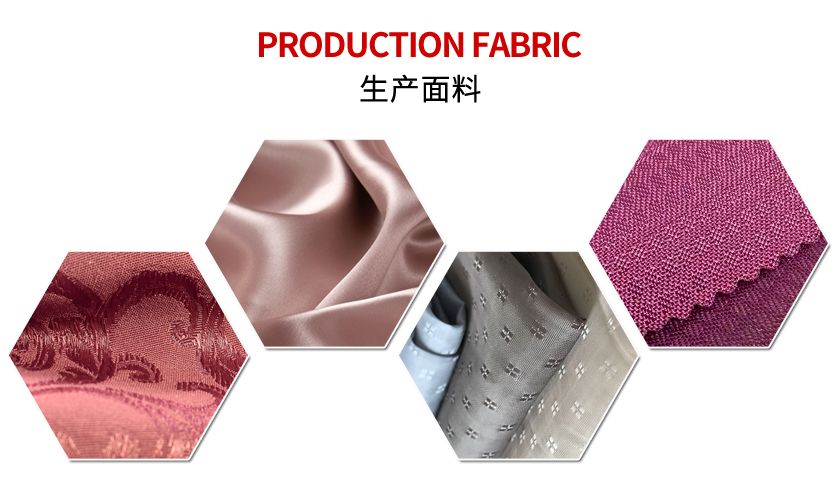

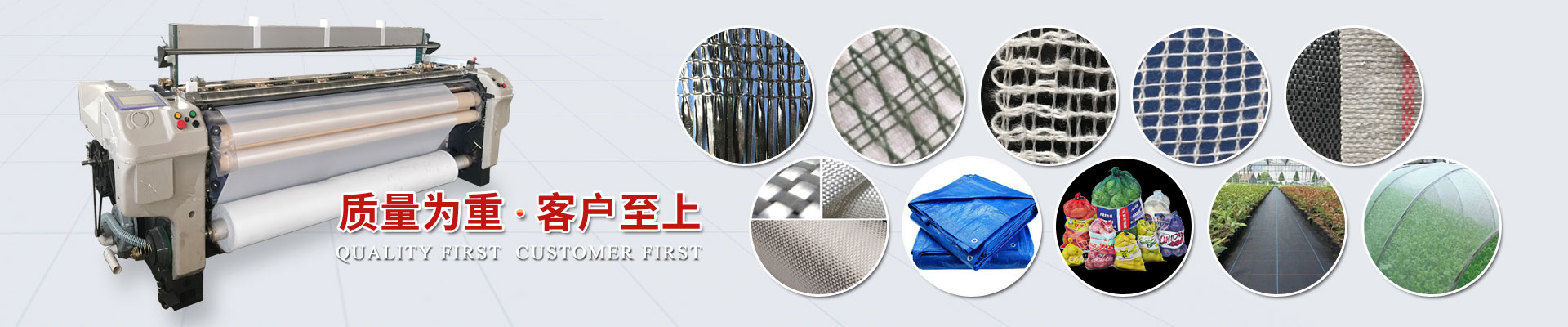

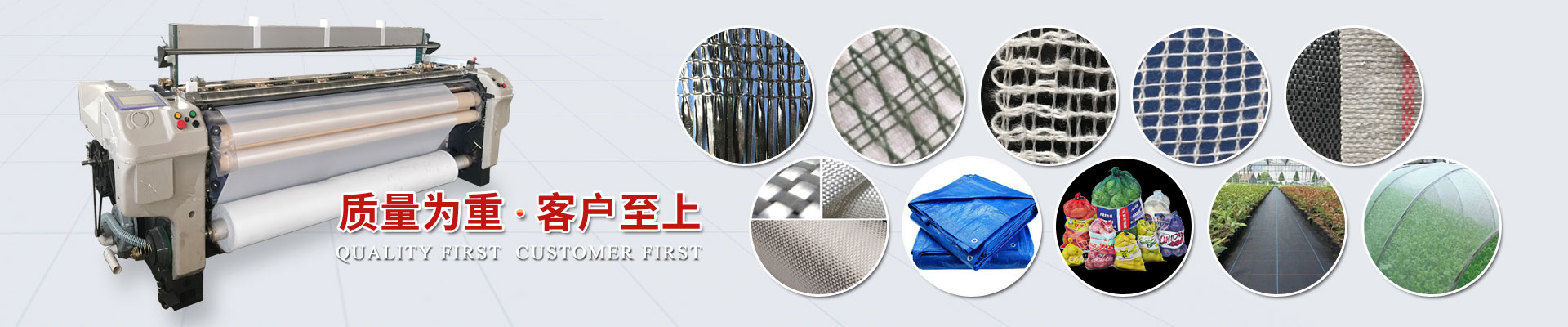

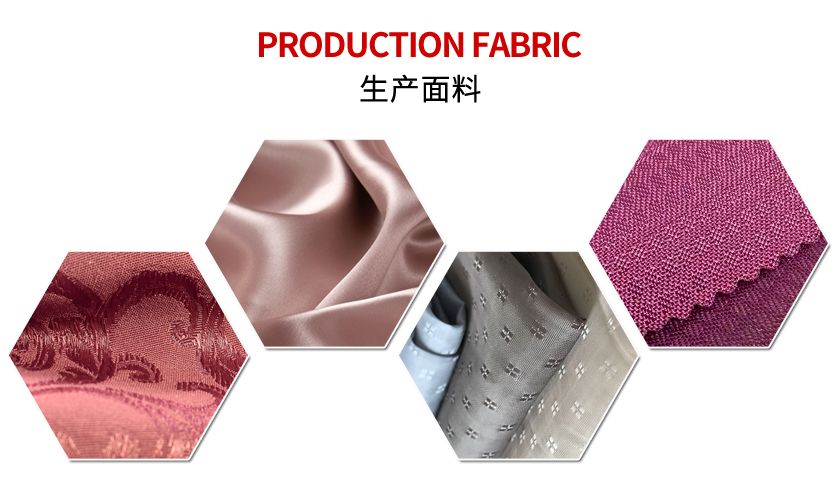

JWS408 heavy duty high-speed water jet loom is a new model developed by our company on the basis of Japan's Tsuda Ju 405 model. The frame structure of the whole machine is designed comprehensively, and the supporting area of the crossbeam is expanded. The stability of the whole machine is greatly improved. It has excellent seismic performance, and is more stable in beating up, which ensures the high quality of the production fabric; Innovative designs have been made in transmission, heald lifting by mouth, let off and crimp system, which are especially suitable for high-speed and stable weaving of heavy fabrics with high gram weight and high density.

Upgrade:

1. Strong frame structure: the independent box frame with high rigidity on both sides can reduce the vibration during high-speed operation. Due to the reduction of vibration, it can achieve further stable weft insertion and beating motion, so as to ensure the high quality of fabric. The main driving part is arranged in the oil bath environment, so further stable high-speed operation is realized.

2. Stable operation: due to the adoption of strong frame structure and high rigid let off and take-up mechanism, the loom operates more stably, and the weaving range is greatly expanded from light and thin fabrics to medium and thick fabrics, and from low density fabrics to high density fabrics. Even when weaving fabrics with complex weave and unbalanced opening, the vibration is controlled to be very slight, Stable weaving.

3. Jws408 has designed a tension system with higher following ability, which reduces customers' worry about fabric hidden stop. The broken warp of fragile warp yarn is reduced, the opening is clearer and the fabric quality is higher. Warp stabilizer makes weaving of high tension and high weft density fabric more stable.

4. The 4-linkage beating up structure on the optimized wallboard frame is designed. The beating up structure not only moves smoothly, but also has minimal vibration, and is most suitable for weaving requirements, which can make the structure durable. Adopt more reasonable plunger, soft and more stable. The weft insertion structure, pump spring, nozzle and column type one-way valve are improved to make weft insertion more convenient and prolong the service life of water pump.Technical parameters:

1.Nominal reed space:150. 170. 190. 210. 230. 280. 300. 320.340. 360

2.The effective width: 0~ - 500 - mm (standard); 0 - 700 - mm (optional)

3.The quantity of nozzle: single nozzle. double nozzle. three nozzle. four nozzle

4.Openings way: plain. cam. dobby. jacquard

5.Beating-up: 4-linkage beating-up(408solid beating-up shaft)

6.Scissors and feeler: mechanical ceramic scissors; photoelectric weft detector

7. Diameter of beam head: ∮ 800mm, ∮ 1000mm (optional)

8. Motor power: 1.5kw-5.4kw

9. Let off and take up: mechanical and electronic

10. Diameter of cloth: Φ 520mm, external coiling 600mm, out loom wind: 800mm